Fabricating in a Digital Age: Where Pixels Meet Production at HollyFab

How HollyFab is Leading the Future of Digital Fabrication

Where Ideas Get Made!

In an industry that once relied solely on sparks, steel, and sweat, the metal fabrication world is undergoing a powerful transformation—and at HollyFab, we're proud to be driving that change.

From laser precision to digital design, today’s fabrication is smarter, faster, and more adaptable than ever. At HollyFab, we’ve fused craftsmanship with cutting-edge software and automation to deliver results that are as refined as they are rugged.

From Blueprint to Build: Our Digital Workflow

Gone are the days of hand-drawn schematics and trial-and-error prototyping. At HollyFab, every project begins with digital precision. Using the latest in 3D modeling and CAD software—including Autodesk Fusion 360, SolidWorks, and AutoCAD—our team creates detailed digital designs that allow for real-time adjustments, stress simulations, and accurate previews before we ever touch a sheet of metal.

These tools help us collaborate more efficiently with clients, reduce errors, and streamline the entire fabrication process—from concept to finished product.

Precision Meets Power: Technology in the Shop

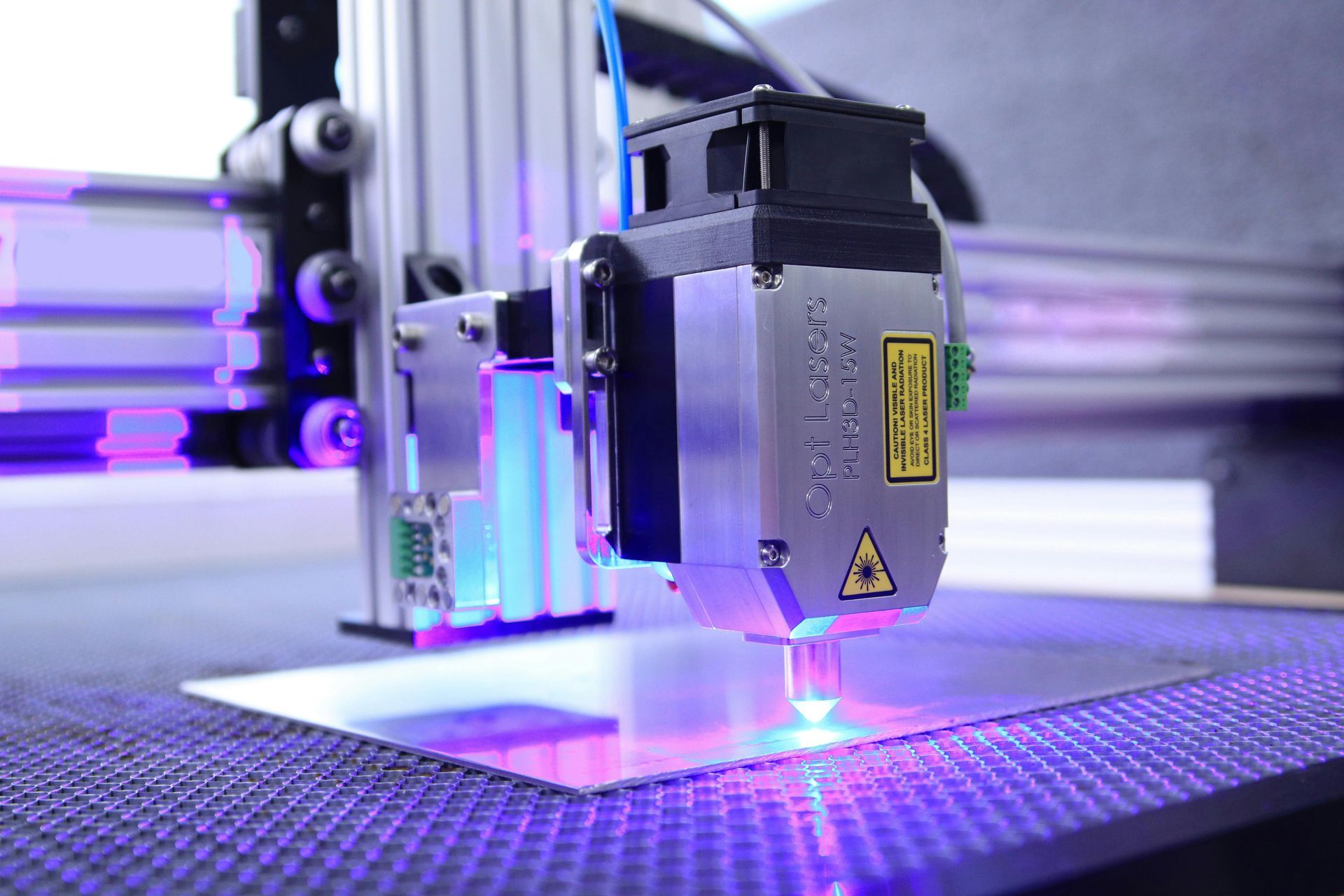

Our commitment to innovation doesn’t stop at the screen. On the shop floor, HollyFab is equipped with advanced digital machinery that turns our models into reality with unmatched speed and accuracy. This includes:

- CNC Plasma Cutters for intricate and heavy-duty metal cutting

- Laser Cutters for clean, high-precision detailing

- Robotic Welding Systems for consistent, high-strength joins

- Press Brakes with CNC Controls for perfect bends and forms

- Automated Toolpathing & Nesting Software for optimal material use

With real-time syncing between our design software and machines, we’re able to move from file to fabrication seamlessly—cutting down lead times while ensuring exact results.

Smarter Materials, Better Builds

At HollyFab, we don’t just make metal products—we engineer smarter, stronger solutions. By integrating our digital tools with material data libraries and performance analysis software, we’re able to select the ideal alloys and finishes for every job.

Whether it’s stainless steel for corrosion resistance, aluminum for lightweight applications, or custom finishes for aesthetics and durability, our tech-driven approach ensures we get it right the first time.

The Human Touch, Elevated by Tech

While we’re proud of our machines and software, we know that fabrication is still, at its heart, a craft. What sets HollyFab apart is how we combine modern tools with decades of hands-on experience. Our team understands the subtleties of metal—and we use our digital tools not to replace craftsmanship, but to enhance it.

We’re not just building parts. We’re building smarter processes, stronger products, and long-term partnerships with clients who value quality and innovation.

Why It Matters

Fabricating in a digital age means faster turnarounds, more customization, tighter tolerances, and less waste. It means we can prototype quickly, adjust on the fly, and scale when needed. And for our clients—it means confidence that their project will be done right, on time, and on budget.

At HollyFab, we’re not just keeping up with the digital age. We’re shaping it.

Want to see what digital fabrication can do for your next metal project? Let’s talk—we’re ready to bring your ideas to life, with precision only possible in today’s digital world.